Shot Blasting Near Me for Beginners

Wiki Article

The Best Guide To Sandblasting Near Me

Table of ContentsThe 9-Minute Rule for Sand Blaster For SaleRumored Buzz on Mobile Sandblasting Near MeThe Mobile Sandblasting Near Me IdeasThings about Abrasive BlastingHow Black Diamond Blasting Sand can Save You Time, Stress, and Money.The Greatest Guide To Harbor Freight Sand Blaster

Steel nozzles will certainly not break when gone down. Economy as well as non-industrial sandblasters for residence or DIY use frequently featured affordable steel nozzles. Based solely on wear resistance boron carbide and also binderless WC last up to seven-time longer than cemented WC. If you bang a boron carbide or silicon nitride nozzle right into a part, grate, or closet wall, after that the nozzle is more probable to split compared to a cement tungsten carbide nozzle.The rough blowing up procedure gets rid of the surface area contamination and converts it into dust. The abrasive blaster can also deeply blast a steel surface to completely remove any rust, range, or followers to a NACE/SSPC "white steel" tidiness grade.

Next, the surface area is peened with small spheres or microbeads to improve the surface area coating. If the part has a rough (high roughness standard, Ra) surface area coating like an as-cast or as-forged surface, after that peening can decently fine-tune the surface area coating. If the part has actually been ground or machined to a smooth or reduced Ra surface, then fired peening will certainly lead to a rougher surface finish.

Portable Sandblaster Can Be Fun For Everyone

Finish, paints, and also adhesives stick better to a rough surface compared to a smooth surface. An abrasive blasted surface produces an anchor account with undercuts and also even more area for finishings and also adhesives to get hold of onto. A sandblast roughed up surface area on a stainless hand rails assists individuals get a much better hold also.

Corrosion as well as rust layers need to be eliminated also, specifically for safety coatings fulfilling the National Organization of Deterioration Engineers (NACE) and also Culture of Surface Area Safety Covering (SSPC) standards. Three factors to get rid of corrosion or rust with unpleasant blowing up are: Corrosion as well as corrosion layers are weak and softer contrasted to the underlying steel.

Pressure Washer Sandblaster Can Be Fun For Everyone

A blast roughed up surface provides mechanical interlocking in between the coating as well as substratum. No, due to the fact that if a surface area is too rough, then thinner safety coatings could not completely cover the surface resulting in pinholes and corrosion of the underlying surface area. Shot, grain, and also abrasive blasting can lower several of the high optimals in a surface profile to boost rust protective finishing performance.Clinical/ Dental Cleaning, coating preparation, etching, and also sprucing up of medical devices and also dental remediations. The investment or mold and mildew material on actors crowns or bridges can be carefully eliminated with a small benchtop sandblaster or micro-blaster. Hip, shoulder, oral and various other bone, as well as joint implants are blast cleaned to satisfy stringent FDA sanitation demands.

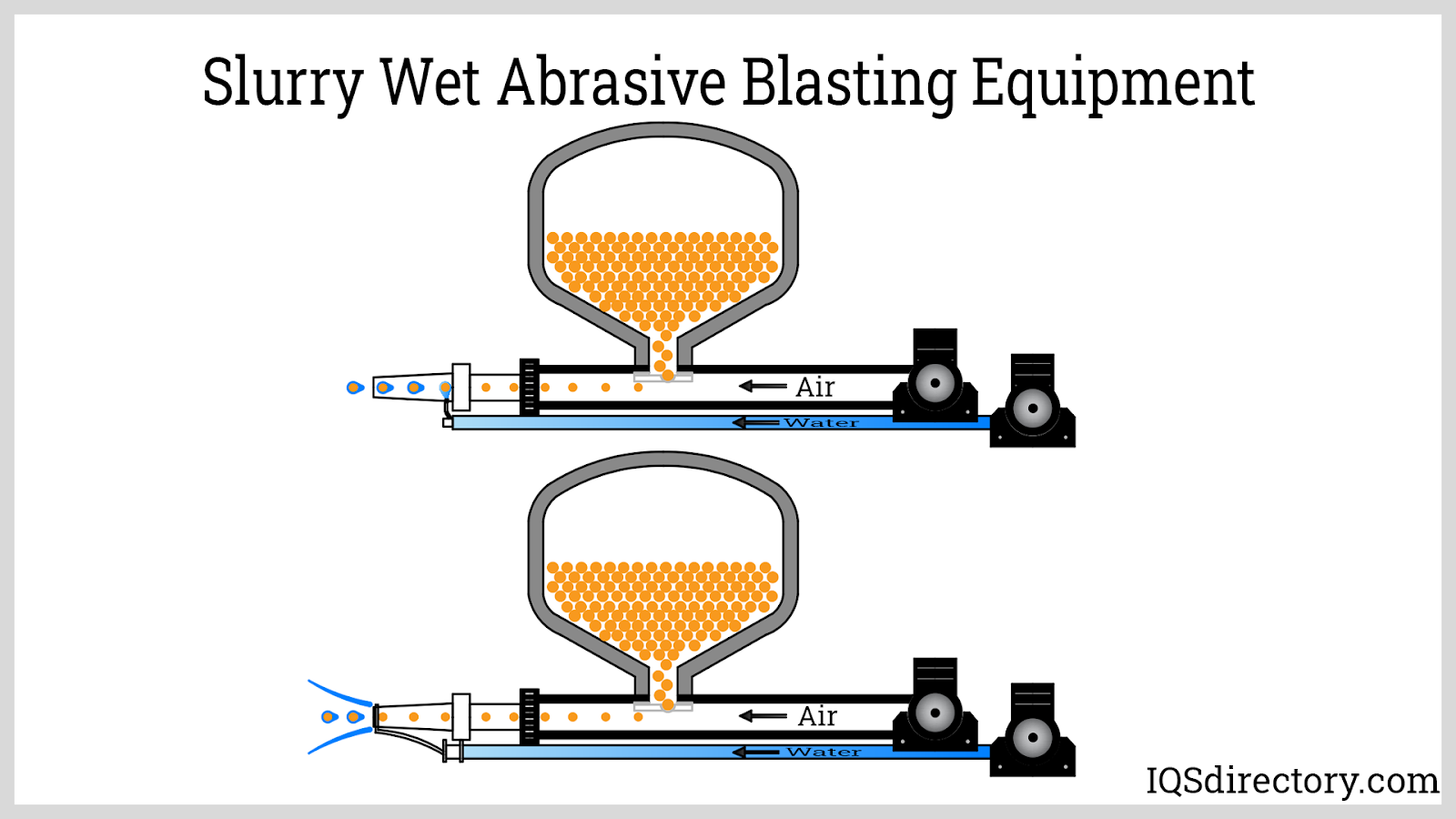

Particular materials such as lead-based paints as well as hefty steels create harmful or harmful dust when blasted. Wet or water blowing up systems reduce the dust issue (sandblasting near me).

Not known Factual Statements About Portable Sandblaster

Sandblasters or sandblasting operators can be hurt throughout abrasive blasting. The high-pressure abrasive stream can damage skin as well as eyes.Soda, completely dry ice, as well as wet blasting maintain parts great throughout blasting. Abrasives and also blast media can obtain lodged into crevices on a component as well as can be tough to eliminate.

Verify the blowing up procedure parameters with an additional examination or trial. Quote the yearly operating and also palatable expenses such as compressed air, water, and also electric power usage. What are the consumable prices such as blast media, put on component replacements, and also system upkeep expenses? What are the labor prices hand sandblaster as well as training requirements? How lots of operators are needed to run the blast system? Is unique safety and also automation system training needed? Send a quote for the sandblast cupboards look at this website together with any extra inquiries to clear up training along with annual approximated operating, maintenance, as well as palatable expenses.

Fascination About Abrasive Blasting

There are three basic parts to this design: an air compressor or pressurized air tank, a hand-held pressure gun with air hose pipe as well as a hopper on top of the gun. The a fantastic read pipe attaches to the air tank, and also the receptacle is loaded with silica sand.

They consist of a huge canister consisting of silica sand under high stress. This is a little bit comparable to the idea behind a spray can. A sandblasting gun, generally a two-handed version, is connected to the port at the top of the canister using a specialized hose pipe that can withstand the abrading affects of the sand.

The Single Strategy To Use For Sand Blaster Harbor Freight

Report this wiki page